With the Indian Carbon Market scheduled for launch in 2026, biochar is emerging as a promising carbon dioxide removal (CDR) technology. Produced via pyrolysis of agricultural residue and organic municipal solid waste, it serves a dual purpose, managing waste sustainably and locking carbon in a stable form for centuries. Read here to learn more.

Annual Waste Generation in India:

- Agricultural residue: ~600 million metric tonnes (MMT)

- Municipal solid waste: ~60 MMT

Much of this is burnt or dumped in landfills, contributing to severe air pollution and GHG emissions (methane, nitrous oxide, CO₂).

Harnessing just 30-50% of this surplus waste could yield 15-26 MMT biochar/year, removing ~0.1 gigatonnes CO₂-equivalent.

Potential of Biochar in India

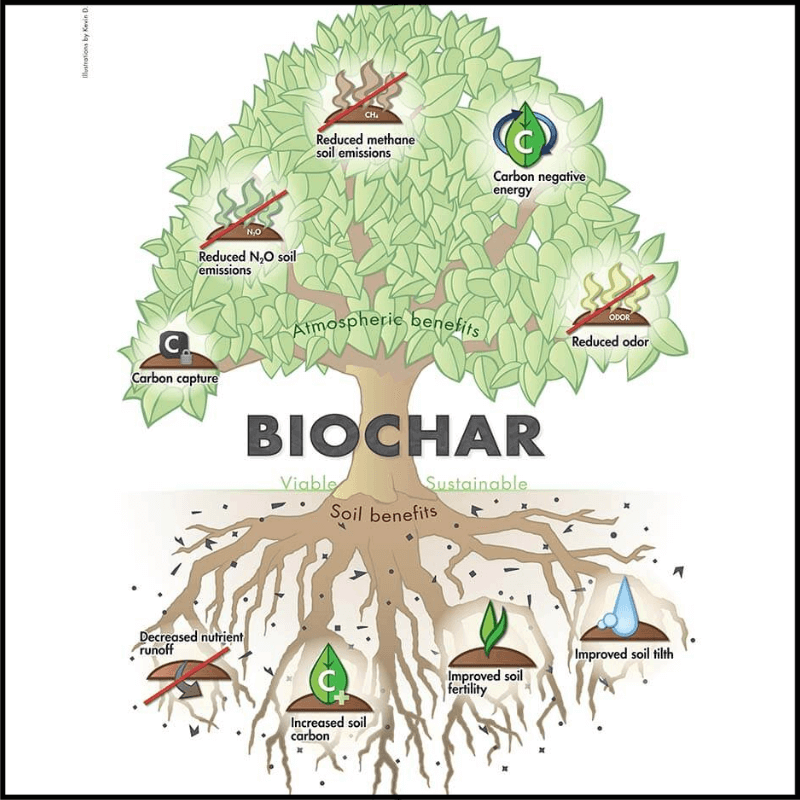

Biochar is a carbon-rich, porous material obtained by heating biomass (agricultural residues, forestry waste, organic municipal solid waste) under limited oxygen conditions, a process called pyrolysis.

Its potential in India lies in three interconnected domains:

- Climate Mitigation

- Biochar locks carbon in a stable form for hundreds to thousands of years, preventing its return to the atmosphere as CO₂ or methane.

- One tonne of biochar can sequester 5–3 tonnes of CO₂-equivalent emissions.

- Contributes to India’s net-zero 2070 goal and commitments under the Paris Agreement.

- Waste Management

- Can process 600+ MMT/year of agricultural residue and 60+ MMT/year of organic MSW, reducing stubble burning and methane from landfills.

- Soil Health & Productivity

- Improves soil structure, aeration, and moisture retention.

- Increases cation exchange capacity (CEC), enhancing nutrient uptake and reducing fertiliser runoff.

Byproducts of Biochar Production

Production via pyrolysis yields two other valuable products:

Byproduct |

Characteristics |

Potential Uses |

Syngas (CO, H₂, CH₄) |

A combustible gas mixture produced during pyrolysis |

|

Bio-oil |

Dark liquid containing phenols, acids, and bio-chemicals |

|

Example: A 1 tonne/day pyrolysis plant can produce ~300 kg biochar, 400 Nm³ syngas, and 100–150 litres bio-oil, enough to run a 50-60 kW generator.

In the Construction Sector

- Cement Replacement in Concrete

- It can replace up to 30% of cement in some mixes, reducing cement’s carbon footprint (cement production emits ~0.9 tonnes CO₂ per tonne).

- Lightweight Aggregate

- Porous biochar can be used as a lightweight filler in concrete, plaster, and insulation panels.

- Thermal & Moisture Regulation

- Acts as a natural humidity regulator in walls.

- Increases insulation, reducing building energy needs.

- Circular Economy Linkage

- Converts local biomass waste into construction-grade material, reducing reliance on virgin resources.

Why Biochar Remains Underrepresented in Carbon Credit Systems

- Measurement & Verification Challenges: Carbon permanence and sequestration efficiency vary by feedstock and production conditions. Difficulty in setting standardised MRV protocols for carbon markets.

- High Initial Costs: Small-scale farmers and waste processors cannot easily afford pyrolysis equipment.

- Policy Gaps: Current Indian carbon offset frameworks focus more on renewable energy and energy efficiency projects than carbon removal.

- Fragmented Supply Chains: Biomass availability is seasonal and region-specific, making year-round operations difficult.

- Awareness Deficit: Limited knowledge among policymakers, farmers, and industries about biochar’s co-benefits beyond carbon sequestration.

Enabling Large-Scale Adoption of Biochar

- Policy & Carbon Market Integration

- Include biochar explicitly in India’s Carbon Credit Trading Scheme (CCTS) with approved MRV methodologies.

- Offer upfront subsidies or tax breaks for pyrolysis plants.

- Decentralised Production Hubs: Promote village-level pyrolysis units linked with FPOs (Farmer Producer Organisations) to process crop residues locally.

- Byproduct Monetisation: Develop bio-oil upgrading refineries and syngas-fed mini-grids to improve project economics.

- Construction Sector Linkages: Mandate green material quotas in public infrastructure projects, enabling demand pull for biochar-based cement alternatives.

- Awareness & Capacity Building: National campaigns and training for farmers, municipalities, and construction firms on its’s applications.

- R&D Support: Fund research on improving yield, quality consistency, and integration with existing waste management systems.

Way forward

- Policy Integration

- Recognise biochar in the Indian Carbon Credit Trading Scheme (CCTS).

- Develop MRV protocols for permanence and quality verification.

- Technology & Infrastructure

- Region-specific R&D to optimise feedstock use.

- Promote decentralised pyrolysis units via Farmer Producer Organisations (FPOs).

- Market Development

- Incentivise biochar-based construction materials and wastewater treatment solutions.

- Monetise syngas and bio-oil to improve project viability.

- Employment & Rural Benefits

- Potential to create 5.2 lakh rural jobs.

- Reduce fertiliser use by 10-20%, increase yields by 10-25%.

Conclusion

Biochar is one of the few carbon-negative technologies that can simultaneously address waste management, soil restoration, renewable energy, and climate goals. For India, its large biomass base is a natural advantage.

However, mainstreaming it will require market incentives, technological standardisation, and cross-sectoral collaboration, linking farmers, municipalities, industry, and carbon markets in a single value chain.

Related articles:

Leave a Reply