India plans to produce bio-bitumen from biomass to reduce imports and tackle stubble-burning issues in road construction. Read here to learn more.

Bitumen is a substance produced through distillation of crude oil which removes lighter crude oil components like gasoline and diesel, leaving the heavier bitumen behind.

Deposits can also occur naturally at the bottom of ancient lakes, where prehistoric organisms have decayed and been subjected to heat and pressure.

It is known for its waterproofing and adhesive properties and is commonly used in the construction industry, notably for roads and highways.

Bio-Bitumen

Bio-bitumen is a sustainable and eco-friendly alternative to traditional bitumen derived from petroleum.

It is produced from renewable organic materials, such as agricultural residues, forestry waste, and other biomass.

The use of bio-bitumen in construction, particularly in road building, offers several environmental and economic benefits.

Production of Bio-Bitumen

Bio bitumen can be produced through various processes, including:

- Pyrolysis: Thermal decomposition of organic material at high temperatures in the absence of oxygen, producing bio-oil that can be further processed into bio bitumen.

- Hydrothermal Liquefaction: Converting biomass into a liquid phase under high pressure and temperature, resulting in a bio-crude that can be refined into bio-bitumen.

- Fermentation and Biochemical Processes: Using microorganisms to break down biomass into bio-oil, which is then processed into bio bitumen.

Benefits of Bio-Bitumen in Road Construction

- Environmental Sustainability:

- Reduction in Greenhouse Gases: Lower carbon footprint compared to traditional bitumen as it is derived from renewable sources.

- Decreased Dependency on Fossil Fuels: Reduces reliance on petroleum, promoting energy security and diversification of energy sources.

- Waste Utilization:

- Agricultural Residues: Utilizes crop residues, such as straw and husks, which are often left over after harvest.

- Forestry Waste: Incorporates wood waste, sawdust, and other by-products from forestry operations.

- Economic Benefits:

- Local Production: Can be produced locally using regionally available biomass, reducing transportation costs and supporting local economies.

- Cost-Effective: Potentially lower production costs as it uses waste materials that would otherwise be discarded.

- Performance and Durability:

- Comparable Properties: Bio bitumen can be engineered to meet or exceed the performance characteristics of traditional bitumen, such as durability, flexibility, and resistance to temperature variations.

- Improved Road Quality: This can contribute to better road quality and longevity, reducing maintenance costs over time.

Role in Reducing Stubble Burning

- Stubble Management:

- Utilization of Crop Residues: By converting agricultural residues, such as paddy straw and wheat straw, into bio bitumen, farmers have an alternative use for the biomass that would otherwise be burned.

- Economic Incentives: Provides farmers with an economic incentive to collect and sell their crop residues instead of burning them, thereby reducing air pollution and health hazards associated with stubble burning.

- Environmental Impact:

- Reduction in Air Pollution: Decreases the incidence of stubble burning, which significantly contributes to air pollution in many agricultural regions, especially in countries like India.

- Improvement in Soil Health: Prevents the degradation of soil quality that occurs due to the burning of crop residues, promoting sustainable agricultural practices.

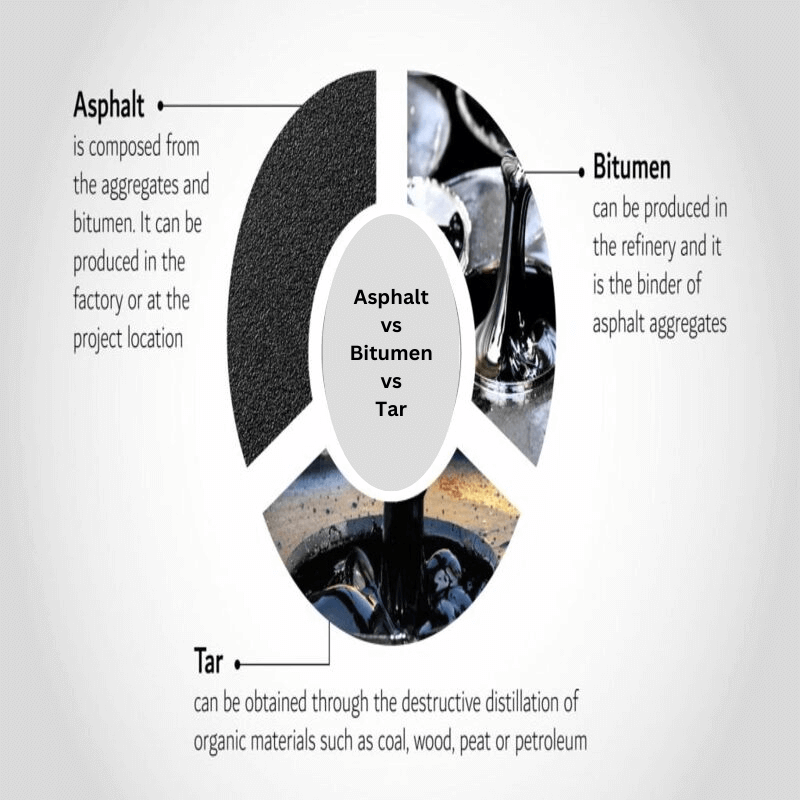

Bitumen vs Asphalt vs Tar

While bitumen, asphalt, and tar are all used in construction and industrial applications, they differ significantly in their source, composition, properties, and primary uses.

Bitumen |

Asphalt |

Tar |

|

Source and composition |

Naturally occurring or derived from crude oil. |

A mixture of bitumen and aggregates. |

Derived from the destructive distillation of organic materials like coal. |

Primary uses |

Binder in asphalt, waterproofing, and sealing. |

Road construction and paving.

|

Sealant, protective coatings, and historically in road construction. |

Durability and performance |

Provides adhesive and waterproofing properties. |

High durability, flexibility, and water resistance.

|

Good adhesive and waterproofing properties, but are less commonly used due to health and environmental concerns. |

Environmental concerns |

Safer than tar but still has some environmental concerns. |

Generally considered safe for use in construction, but dust and fumes can be an issue. |

Contains harmful chemicals and is less commonly used due to health and environmental concerns. |

Why in the news?

India is looking to start large-scale production of bio-bitumen from biomass or agricultural waste, a move that would help reduce imports of the material used for asphalting of roads while also addressing the persistent issue of stubble burning.

- The Central Road Research Institute (CRRI) will collaborate with the Indian Institute of Petroleum, Dehradun to construct a 1 km road stretch using bio-bitumen.

- The success of this pilot study could lead to the commercialization and transfer of technology to private entities or the public sector for mass production of bio-bitumen which will be utilized for construction of the national highways.

- India currently imports about half of its annual requirement of bitumen and the target is to replace imports with bio-bitumen over the next 10 years.

Bitumen Production in India

- Domestic Production:

- India produces bitumen as a byproduct in its oil refineries.

- Major Indian oil companies like Indian Oil Corporation (IOC), Bharat Petroleum Corporation Limited (BPCL), and Hindustan Petroleum Corporation Limited (HPCL) are key producers.

- Quality and Grades:

- India produces various grades of bitumen, including VG-10, VG-20, VG-30, and VG-40, which cater to different climatic and usage conditions.

Import Burden:

- Demand vs. Supply:

- India’s rapid infrastructure development has led to increased demand for bitumen.

- Domestic production falls short of meeting this demand, leading to significant imports.

- Import Statistics:

- India imports bitumen primarily from the Middle East, especially from countries like Iran, UAE, and Bahrain.

- The annual import burden runs into hundreds of millions of dollars, affecting the country’s trade balance.

- Economic Impact:

- The dependency on imports exposes India to price volatility in the global oil market.

- High import costs impact the overall cost of infrastructure projects, making them more expensive.

Conclusion

Bio-bitumen represents a promising advancement in sustainable construction materials. By offering an eco-friendly alternative to petroleum-based bitumen, it not only supports environmental sustainability but also addresses critical issues such as waste management and stubble burning.

The use of bio-bitumen in road construction can lead to better air quality, healthier ecosystems, and a reduction in the reliance on non-renewable resources. As research and development in this field continue, bio-bitumen has the potential to play a significant role in the future of green infrastructure.

India’s reliance on imported bitumen poses significant economic challenges, but the development of bio-bitumen presents a promising solution.

By leveraging renewable resources and investing in research and development, India can reduce its import burden and enhance the sustainability of its infrastructure projects.

Government support, industry collaboration, and technological advancements will be crucial in realizing the potential of bio-bitumen as a viable alternative to traditional bitumen.

Read: Road Infrastructure in India

-Article by Swathi Satish

Leave a Reply