India is the world’s largest producer and the third largest user of natural rubber and one of the world’s fastest expanding economies. But the rubber industry in India faces many problems. Read the article to know more about natural rubber and the rubber industry.

As part of India’s expanding involvement in the global economy, the Indian rubber industry has grown in strength and importance. India is the world’s largest producer and the third largest user of natural rubber and one of the world’s fastest expanding economies.

With an annual growth rate of 8-9%, rising foreign exchange reserves, rapid expansion in capital markets, and FDI inflows, India proudly claims the title of the world’s second-fastest-growing major economy. It has a high concentration of vehicle manufacturing and the existence of large and medium companies in South India.

Global rubber production was considered extremely volatile in the last few years. Compared to the rest of the globe, India’s rubber production is stable at 6% yearly. The Indian rubber sector has expanded dramatically over the years.

Natural Rubber

- Natural rubber is a polymer of the chemical molecule called isoprene. Rubber is a cohesive elastic solid derived from the latex of several tropical trees.

- It is a native of the Amazon basin and was introduced to countries in the tropical belts of Asia and Africa in the late nineteenth century.

- Hevea brasiliensis, often known as the Para rubber tree after the Brazilian port of Para, is a fast-growing, moderately strong, perennial tree that can reach a height of 25 to 30 metres.

- The rubber tree has a straight trunk and thick, slightly soft, light brownish-grey bark. It can live for a hundred years or more.

- The rubber tree may live for a hundred years or even more. But its economic life period in plantations, on general considerations, is only around 32 years – 7 years of the immature phase and 25 years of the productive phase.

Rubber Growing Areas

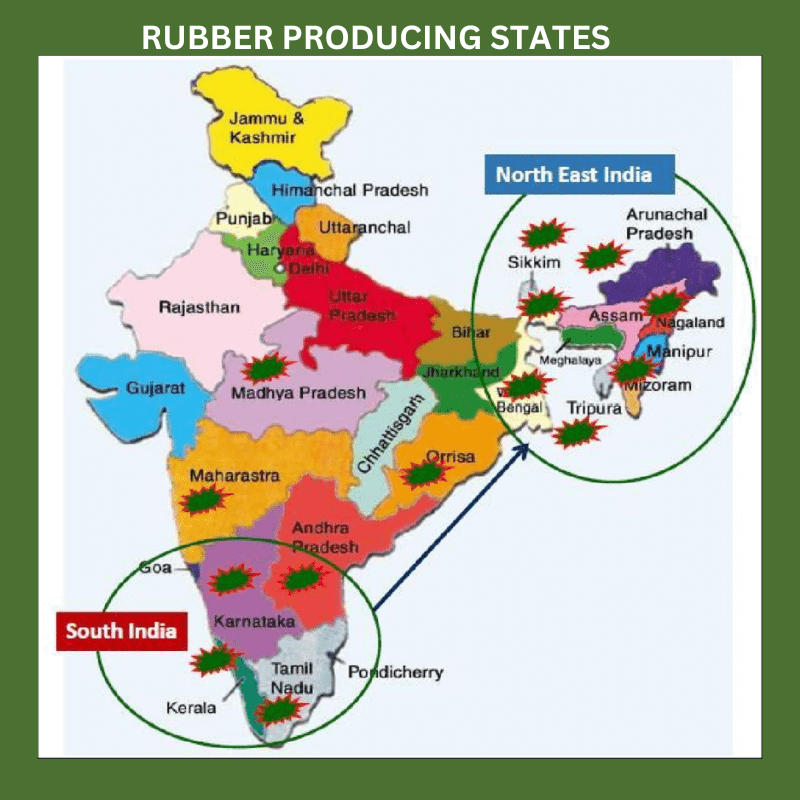

On the basis of agro-climatic conditions, India’s rubber-growing regions can be divided into two major zones: traditional and non-traditional.

Traditional Areas

Rubber growing in India has traditionally been limited to the hinterlands of the southwest coast, primarily in Tamil Nadu’s Kanyakumari District and Kerala.

Non-traditional regions

Rubber is presently farmed in the hinterlands of coastal Karnataka, Goa, Maharashtra’s Konkan Region, coastal Andhra Pradesh and Orissa, the northeastern provinces, and the Andaman and Nicobar Islands, among other places.

Climate requirements for Rubber Cultivation

Soil

- Trees require well-drained, weathered soils.

- Lateritic, alluvial, sedimentary, and non-lateritic red soils are optimal for growing these trees.

- Deep, friable, well-drained soils are optimal for root development, and acidic soils are also suitable.

Temperature

- For the greatest outcomes, a humidity of roughly 80%, 2000 hours of sunshine, and the absence of high winds are also required.

- Rubber is a tropical tree that demands high temperatures all year, ranging from 20° to 35° C, or an average monthly mean of 27° C.

- Temperatures below 20°C are harmful.

Precipitation

- The Hevea rubber tree grows best in areas with evenly distributed rainfall throughout the year, at least 100 rainy days per year,

- Annual average rainfall of at least 200 cm is ideal.

Major Uses

- Rubber is used for a wide range of applications, from erasing pencil markings to creating tyres, tubes, and a wide range of industrial products.

- Because of its great tensile strength, vibration-dampening characteristics, and tear resistance, natural rubber is favoured over synthetic rubber.

- As a result, it is critical for the construction and automobile industries.

- The expansion of the vehicle business in several nations is expected to enhance demand for natural rubber manufacturing.

- The increased need for latex items such as catheters, gloves, and belts is also expected to contribute to the expansion of the rubber market.

Rubber Industry in India

India is the third largest producer, the fourth largest consumer of natural rubber and the fifth largest consumer of natural and synthetic rubber together in the world.

- With around 6000 units comprising 30 large scale, 300 medium scale and around 5600 SSI/tiny sector nits, manufacturing 35000 rubber products, employing 400 hundred thousand people, including around 22000 technically qualified support personnel, with a turnover of Rs.200 billion and contributing Rs.40 billion to the National Exchequer through taxes, duties and other levies, the Indian Rubber Industry plays a core sector role in the Indian national economy.

The wide range of rubber products manufactured by the Indian rubber industry comprises all types of heavy-duty earth-moving tyres.

- Auto tyres, tubes, automobile parts, footwear, belting, hoses, cycle tyres and tubes, cables and wires, camelback, battery boxes, latex products, pharmaceutical goods, and moulded and extruded goods for mass consumption.

- The products manufactured also cover hi-tech industrial items.

- The important areas which the industry caters to include all three wings of defence, civil, aviation, aeronautics, railways, agriculture, and transport as also textile engineering industries, pharmaceuticals, mines, steel plants, ports, family planning programmes, hospitals, sports, practically to every conceivable field.

The rubber industry in India is basically divided in two sectors –

- tyre and

- The non-tyre sector produces all types of auto tyres, conventional and radial tyres, and exports to advanced countries like the USA.

- The non-tyre sector comprises the medium-scale, small scale and tiny units.

- It produces high-technology and sophisticated industrial products.

- The small-scale sector accounts for over 50% of the production of rubber goods in the non-tyre category.

- Going by share of rubber consumption, the automotive tyre sector is the single largest sector accounting for about 50% of consumption of all kinds of rubbers, followed by bicycle tyres and tubes 15% footwear12%, belts and hoses 6%, camelback and latex products 7%.

- All other remaining rubber products put together account for 10%.

The plantation sector with an estimated production of over 631 hundred thousand tons of natural rubber and a projected production of more than one million tons in near future, contributes to the rapid growth of the Indian rubber industry.

- Kerala, with a total area of 3.84 lakh hectares under rubber cultivation and an annual production of 3.70 lakh tonnes, produces over 90% of India’s natural rubber.

- Of the total area, 92 percent is represented by small holdings with an average area of around 0,5 hectares.

- There are about 10 Lakh growers and 3.5 Lakh workers engaged in the rubber sector of which more than 90 percent belong to Kerala.

- A sound network of intermediate rubber units engaged in rubber compounding, crumb rubber manufacture etc., exist in the state.

Market Capitalization

The Indian Rubber Industry is approximately 6000 units in size, with 30 big scale, 300 middle scales, and over 5600 small scale and tiny sector units. Such units produce over 35000 rubber goods, employ 400 thousand people, including 22000 technically competent support employees, and provide Rs. 40 billion to the national exchequer through taxes, customs, and other levies.

- The Indian Rubber Industry is important to the Indian economy since the rubber plantation industry in India generates about 630 thousand tonnes of natural rubber per year, with a predicted production of more than one million tonnes in the near future.

- Rubber output in India is between 6 and 7 lakh tonnes per year, amounting to Rs. 3000 crores. Ribbed Smoked Sheets (RSS) account for 70% of total rubber production in India and are also imported by India, accounting for 45% of total rubber imports. Today, the Indian Rubber Industry has a turnover of Rs 12000 crores.

- The tyre sector consumes the majority of the rubber, accounting for over 52% of India’s total production. Kerala is the largest rubber consumer, followed by Punjab and Maharashtra. Despite being one of the main producers of rubber, India still buys rubber from other countries. At the moment, India imports approximately 50000 tonnes of rubber every year.

India’s Rubber Production Situation

According to FAO Stat 2019, India is the world’s fourth-largest producer and user of rubber.

- Consumption

The transportation sector consumed the most rubber, followed by the footwear industry. - Exports

The amount of natural rubber exported from India for the fiscal year 2020 totalled above 12 thousand metric tonnes.

Germany, Brazil, the United States, and Italy were the top importers of natural rubber from India.

Automobile tyres and tubes, footwear, medicinal goods and hoses, coats and aprons were among the export items.

Rubber Producing Areas

- The first rubber plantations in India were established in 1895 on the hill slopes of Kerala.Commercial rubber cultivation, on the other hand, began in 1902.

- Kerala is India’s top producer of natural rubber. Kottayam, Kollam, Ernakulam, and Kozhikode generate nearly all of the state’s rubber.

- Tamil Nadu’s main rubber-producing districts include Nilgiri, Madurai, Kanniyakumari, Coimbatore, and Salem.

- Chikmagalur and Kodagu are the key producing districts of Karnataka.

- Other states that produce rubber include Tripura, Assam, Andaman & Nicobar, Goa, and others.

Problems faced by the Rubber industry

- A significant decrease in rubber productivity per hectare.

- The constant drop in natural rubber prices, along with high labour costs, has driven many growers (75 per cent of small and marginal farmers) to refrain from tapping.

- Rubber growers and tyre companies have competing interests. Unrestricted enormous imports by larger tyre firms reduced domestic demand; however, MSME and other small industries that rely on the domestic supply of natural rubber demanded immediate action.

- Other causes include high input prices, an unusual duty system, inexpensive imports, and the negotiation of Free Trade Agreements with countries that stimulate the entry of finished rubber products into India.

In news

The Rubber Board of India has launched forward-looking initiatives aimed at boosting Indian rubber’s global presence, increasing domestic production, and fostering sustainability, aligning with the objectives of the National Rubber Policy (NRP) 2019.

- Indian Sustainable Natural Rubber (iSNR)

- Promotes environmentally sustainable rubber cultivation practices.

- Encourages the adoption of eco-friendly technologies and methods for natural rubber production.

- Aims to align Indian rubber with global sustainability standards, meeting the demand for responsibly sourced materials.

- INR Konnect Platform

- A digital platform to strengthen India’s rubber industry by connecting stakeholders across the value chain.

- Facilitates trade, knowledge sharing, and collaboration among producers, processors, and consumers.

- Enhances traceability and transparency in the supply chain, making Indian rubber more competitive globally.

National Rubber Policy (NRP) 2019: Objectives and Alignment

The National Rubber Policy 2019 provides a framework to develop a sustainable and competitive rubber industry in India. The recent initiatives align with its goals, which include:

- Sustainability: Encouraging practices that reduce environmental impact and promote biodiversity.

- Competitiveness: Enhancing productivity and reducing costs to compete in global markets.

- Technology & Innovation: Fostering research and development to improve yield, quality, and sustainability.

- Infrastructure Development: Strengthening facilities for production, processing, and export.

Frequently Asked Questions (FAQs)

Q. Which is the largest producer of rubber in India?

Ans: Kerala is the largest rubber-producing state in India. Rubber is cultivated in 16 states of India.

Q. Which country is the largest consumer of rubber?

Ans: China is by far the largest consumer of natural rubber worldwide. China uses natural rubber for a variety of manufacturing uses, including automobile and tyre manufacturing, in particular.

Article Written By: Atheena Fathima Riyas

I am Liberian rubber farmer and is impressed with India rubber sector and economic returns. The establishment of RSS factories is interesting.

On the contrary smallholder farmers is challenged with lack of markets to sell their rubber and making an appeal through this medium to invite buyers of to commodity to alleviate the situation.