Critical minerals are essential for the manufacturing of high-tech products, renewable energy technologies, defense equipment, and various other industrial applications. Their importance has grown significantly in the context of the global push towards clean energy and technological innovation. Read here to learn more.

India, with its vast geological diversity, holds significant reserves of several critical minerals, positioning it as a key player in the global supply chain.

The exploration, extraction, and management of these minerals are crucial for India’s economic and strategic interests.

What are Critical minerals?

Critical minerals are elements that are essential to the functioning of modern societies and economies but face potential supply risks due to geological scarcity, geopolitical issues, or other factors.

Critical minerals are essential to the economic and security interests of nations due to their fundamental role in manufacturing high-tech products, renewable energy technologies, electric vehicles (EVs), defense systems, and various other applications.

The significance of these minerals has increased with the global transition towards clean energy and the growing reliance on technology-driven economies.

- The definition of what constitutes a “critical” mineral can vary between countries, depending on their specific industrial needs, technological progress, and strategic security considerations.

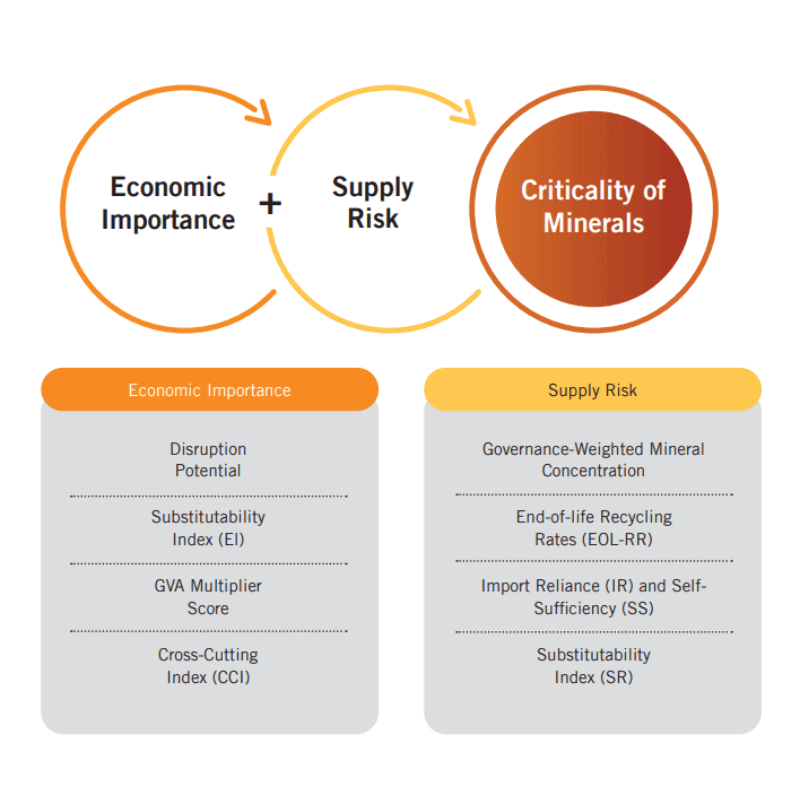

- One of the cited definitions suggests that a mineral is labeled as critical when the risk of supply shortage and associated impact on the economy is (relatively) higher than the other raw materials.

- The risk of supply shortage would ideally capture import dependence, recycling potential, and substitutability of the mineral in question.

Key Critical Minerals and Their Uses

- Lithium, Cobalt, and Nickel: Essential for lithium-ion batteries used in electric vehicles, portable electronics, and energy storage solutions.

- Rare Earth Elements (REEs): A group of 17 elements used in high-strength magnets, electronics, wind turbines, and military applications. Neodymium and dysprosium, for example, are critical for permanent magnets in motors.

- Copper: Vital for electrical wiring, renewable energy systems, and electric vehicles due to its high electrical conductivity.

- Titanium: Used in aerospace for its strength-to-weight ratio, corrosion resistance, and high-temperature performance.

- Platinum Group Metals (PGMs): Essential for catalytic converters in vehicles, fuel cells, and various electronics.

- Graphite: Critical for the anodes of lithium-ion batteries and its lubricating properties in many industrial applications.

Challenges

- Supply Risks: The supply of critical minerals is concentrated in a few countries, creating vulnerabilities to geopolitical tensions, trade disputes, and regulatory changes.

- Environmental Impact: Mining and processing of critical minerals can have significant environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions.

- Market Volatility: Prices for critical minerals can be highly volatile, influenced by sudden changes in demand, supply disruptions, or speculative trading.

Critical Minerals for India

The government released a list of 30 critical minerals for India in 2023.

- These minerals are Antimony, Beryllium, Bismuth, Cobalt, Copper, Gallium, Germanium, Graphite, Hafnium, Indium, Lithium, Molybdenum, Niobium, Nickel, Platinum Group elements (PGE), Phosphorous, Potash, REE, Rhenium, Silicon, Strontium, Tantalum, Tellurium, Tin, Titanium, Tungsten, Vanadium, Zirconium, Selenium and Cadmium.

The Ministry of Mines has increased its focus on the exploration of these minerals in the country through the Geological Survey of India (GSI) and other agencies.

The Indian Critical Minerals Identification process tries to address five core objectives:

- Supporting economic growth, competitiveness, and job creation.

- Driving research, innovation, and exploration.

- Enhancing global security partnerships with allies.

- Raw material security for state-of-the-art defense.

- Promoting climate action and environmental protection.

However, to achieve the desired objective, the complete value chain from exploration to manufacturing to recycling needs to be addressed, which may be considered the main pillars of the critical mineral value chain.

Five pillars of the critical minerals value chain:

- Upstream exploration

- Upstream mining and extraction

- Midstream- processing, refining, and metallurgy (e.g., semi-finished inputs and materials)

- Downstream- component manufacturing and clean, digital, and advanced technology production (e.g., ZEV manufacturing, aircraft, and semiconductors)

- Material recovery and recycling

Why in the news?

India launched the second part of its critical minerals auction worth an estimated 30 trillion rupees (about $362 billion).

- A total of 18 critical mineral blocks, including tungsten, vanadium, cobalt, and nickel, will be auctioned in eight states across the country, including Chhattisgarh, Madhya Pradesh, Karnataka, Maharashtra, and Rajasthan.

- Seventeen mineral blocks have been put up for a composite license, while one block is for a mining lease, it added. A composite license includes a license to examine a block and mine it afterward.

- Five states – Maharashtra, Madhya Pradesh, Haryana, Chhattisgarh, and Rajasthan – will auction blocks for exploration licenses of critical minerals, separately.

Strategic Importance and Challenges

The strategic importance of these minerals cannot be overstated, given their applications in defense, renewable energy, and high-tech industries.

India’s policy framework, including the National Mineral Policy and the initiatives under the Aatmanirbhar Bharat (Self-Reliant India) program, emphasizes the exploration and development of these critical minerals.

However, challenges remain, including environmental concerns, the need for advanced technology for extraction and processing, and the geopolitical complexities of international mineral trade.

Way forward

To address these challenges, India is investing in research and development, international partnerships, and policies to encourage domestic production of critical minerals. This includes efforts to attract foreign investment, enhance mining technologies, and ensure sustainable and environmentally friendly extraction practices.

- There is a need for establishing a National Institute or Centre of Excellence on critical minerals on the lines of CSIRO which is an Australian Government corporate entity and one of the world’s largest mission-driven multidisciplinary science and research organizations.

The development and management of critical mineral resources are pivotal for India’s ambition to become a leading player in the global market for high-tech products and renewable energy technologies. By securing a stable and sustainable supply of these minerals, India can significantly enhance its industrial, technological, and strategic capabilities on the global stage.

Related articles:

- Mines and Minerals Development Bill, 2021

- Mineral Security Partnership

- Offshore Areas Minerals

- Mining sector in India

-Article by Swathi Satish

Leave a Reply